Consequently, theoretical methods and computer simulations have become the commonly used methods for predicting the nano-phase diagrams in recent years. However, experimental determination of the nano-phase diagram is scarce since calorimetric measurements remain quite challenging at the nanoscale 1, 20, 25. To fully understand the behavior of continuous binary nanoalloys for applications, a knowledge of the phase diagram is required, since the phase diagram can provide important guidance for tuning their thermodynamic and other properties to achieve optimum device performance. For example, Ni-Cu nanoalloys are recognized as efficient catalysts and promising materials for electromechanical devices 3, 4, 7. This will help the experimentalists by guiding them in their attempts to design bimetallic nanocrystals with the desired properties.Ĭontinuous binary nanoalloys have attracted considerable interests owing to their unique physicochemical properties 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25.

the cohesive energy, catalytic activation energy, and order-disorder transition temperature, and the validity is supported by available other theoretical prediction, experimental data and molecular dynamic simulations results. Moreover, the established model can be employed to describe other physicochemical properties of nanoalloys, e.g. By reviewing surface segregated element of different binary nanoalloys, two segregation rules based on the solid surface energy and atomic size have been identified. The congruent melting point of Cu-Au nanoalloys with and without segregation is linearly shifted to higher Au component and lower temperature with decreasing size or increasing shape factor. The liquidus/solidus dropped in temperature, two-phase zone was narrowed, and the degree of surface segregation decreased with decrease in the size or increase in the shape factor.

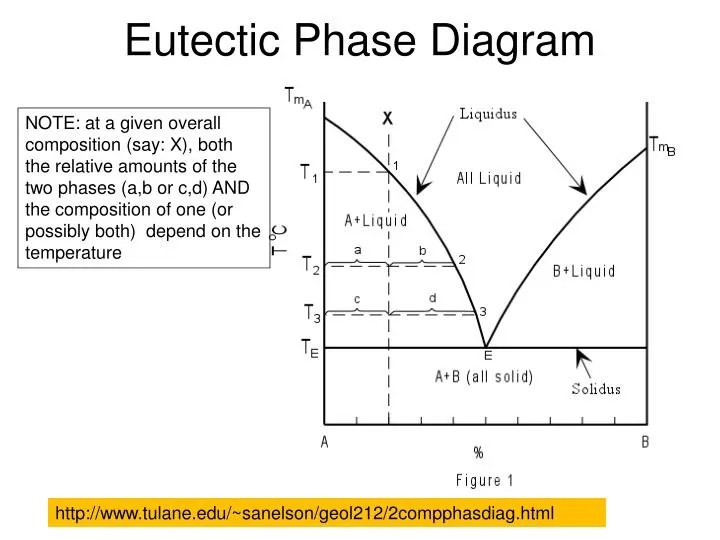

Based on the size-dependent cohesive energy model, we developed a unified nano-thermodynamic model to investigate the effects of the size, shape, and segregation on the phase diagrams of continuous binary nanoalloys. However, experimental determination of the nano-phase diagram is scarce since calorimetric measurements remain quite challenging at the nanoscale. The phase diagrams of continuous binary nanoalloys are important in providing guidance for material designs and industrial applications.

0 kommentar(er)

0 kommentar(er)